Our inverter is used in systems which include inverter electronics mounted close to the motor. Parameterise standardised drive functions or program complex drive tasks.

Flexible solutions to demanding materials handling tasks with decentralised drive concept

Automation made easy! Implement demanding materials handling applications with our decentralised application inverter MOVIFIT® FC in the technology function level design. The technology design provides both the opportunity to operate standardised application modules as well as to implement your system specific requirements through programming. This can be implemented both for simple speed controlled auxiliary axes through to the operation of simple hoist axes or complex conveyor axes.

Our application inverter is equipped with extensive safety functions and supports virtually all common field bus systems. Optimally equipped for a broad range of applications. Also choose our MOVIFIT® FC for energy efficiency. Combine the inverter with our DRU..J series (IE4 motors) energy efficient motors and an efficient brake control. Save energy and costs in the process.

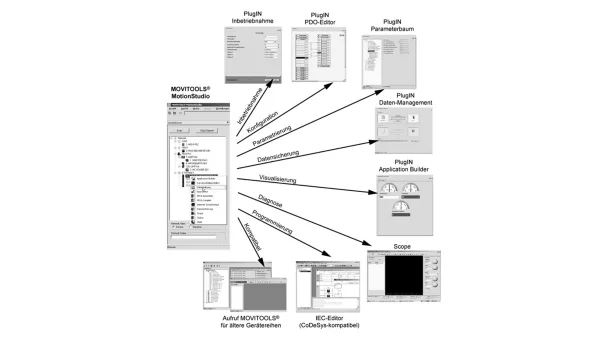

Implement application functions without any time consuming programming in combination with our application modules. Simple parameterisation with the aid of intuitive startup wizards enables the implementation of complex motion sequences such as cam positioning for up to three MOVIMOT®. Your tasks can also be freely programmed using the standard IEC 61131 languages In addition, a complete range of program components is available for individual and tailored solutions. The MOVITOOLS® MotionStudio enables a complete engineering concept. A tool with all the elements necessary for automation and startup of your system.

Our MOVIFIT® FC inverter has more than just internal strengths. The high degree of protection IP65 is standard. Its robust aluminium die cast housing is divided into electronics unit (EBOX) and connection unit (ABOX). A major advantage is the closing mechanism with only one screw. This enables quick assembly and smooth unit replacement for servicing.

Save cost and time on installation as well. The integrated T distributor for energy and communication, the integrated repair switch and digital IOs means that a wide variety of external additional components are no longer required for the installation.

The HygienicPlus design for use in extreme ambient conditions, for example in wet conditions in the beverage industry is also available as standard

Configure your individual product

- Detailed information about your individual product

- CAD data and documentation for your configuration

- Option to directly request a quotation or place an order

Your benefits

-

High flexibility

through the positioning of simple lifting axes to complex conveyor axes on all common bus systems. -

Low total costs

due to energy-optimised brake control, operation of IE2 to IE4 motors and saving on external components. -

Simple startup

due to standardised application modules including evaluation of process relevant decentralised sensor technology. -

High system availability

due to potential pre-startup without controller in operation and fast unit replacement with only one screw. -

Confirmed safety

by means of compliance with certified safety options from secure communication and safe disconnection through to safe motion.

Features

- Decentralised frequency inverter with wide range of functions

- Constant speed control, synchronised motion, simple lifting axes

- Free programming according to IEC 61131

- Integrated T distributor for supply and control voltage up to 6 mm²

- Integrated energy efficient brake management for various brake voltages

- Optional internal (integrated in ABOX) or external braking resistor

- Optional maintenance switch

- Optional incremental encoder connection

- Comprehensive integrated communication interfaces:

- PROFIBUS® (optional PROFIsafe)

- PROFINET® IO (optional PROFIsafe)

- PROFINET® IO via SC RJ POF

- DeviceNETTM

- EtherNETTM/IP

- Modbus/TCP

- Comprehensive safety functionality

- Integrated digital inputs and outputs

- CAN/SBus interface for external components

- Parameterisable application modules (e.g. cam positioning, bus positioning)

- Integrated parameter memory

- Comprehensive diagnostics via LEDs

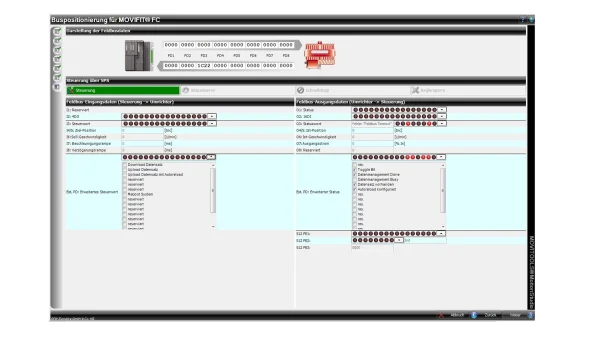

- Expanded parameterisation and diagnostics via MOVITOOLS® MotionStudio or fieldbus

- Plug-in interfaces for energy, motors (power rating) and IOs

- Robust aluminium housing

- Degree of protection IP65 (IP69K optional)

- General approvals: CE, UL, C-Tick

Technical data

- Power range from 0.37 to 4 kW (in two sizes)

- Size BG1: 0.37 to 1.5 kW

- Size BG1: 2.2 bis 4.0 kW

- Voltage range 3 x 380 V to 500 V / 50 Hz to 60 Hz

- 12 DI + 4 DI/O with classic function level and PROFINET® fieldbus

Connection variants

The application inverter consists of an electronics unit (EBOX) and the connection unit shown here (ABOX). The MOVIFIT® connection box (ABOX) is a large connector and is entirely passive. It is available in two designs:

MOVIFIT® standard connection box

MOVIFIT® hybrid connection box

The hybrid connection box (ABOX) of MOVIFIT® from SEW‑EURODRIVE is also a large connector. It also only contains the connection technology All cables for power supply and the motor cables are routed into the ABOX via cable glands and wired to terminals at this point. M12 connectors are provided for digital inputs and outputs. The bus system can be connected via connectors. The bus connectors vary depending on the fieldbus used.

Function level

The function level indicates the functional scope of the software assigned to the MOVIFIT® units in terms of:

- Software functionality

- Processing the digital inputs and outputs

- Local system control

- Startup operation and diagnostics

Technology function level

Parameterisable application modules – standardised application functions

- Standardised functions

- Control and diagnostics via fieldbus

- Parameterisation instead of programming

- Startup and diagnostics using MOVITOOLS® MotionStudio.

Free programming (MOVI-PLC®/MOVITOOLS® MotionStudio)

- Programming in accordance with IEC 61131 (e.g. in LD, FBD, IL, ST, SFC)

- MOVITOOLS® MotionStudio with PLC Editor, Application Builder, etc.

- Multi-level library concept

(application and program modules of the MOVI-PLC® controller series) - PLCopen certified motion blocks

Functional safety

Monitor and react in safety! From safe disconnection (STO) to speed-dependent safety functions (SDI, SLS). Our distributor is also available in conjunction with MOVIMOT® in various safety-related specifications and options.

Functions can be controlled via safe terminals as well as via PROFIsafe. In independent operation our safety options S12 can undertake a local evaluation, processing and disconnection of safety-related signals and functions. A higher-level safety controller is not required in independent operation.

safetyDRIVE

is our contribution to your plant and machine safety. In addition to functionally safe drive technology, we are offering various safety services. safetyDRIVE not only helps you to prevent accidents, but also reduces costs in safety zones and increases productivity.

Click here for more information about safetyDRIVE and the EC Machinery Directive 2006/42/EC.

Safety functions in the MOVIMOT®

Integrated safety technology in our MOVIMOT® gearmotor with inverter

Safety functions in accordance with IEC 61800-5-2:

- Safe disconnection: STO

- Safe stopping SS1 (a) and SS1 (c)

- Safe direction (SDI, SLS)

- Approval in accordance with:

- Category 3 according to EN 954-1:

- Performance level d according to EN ISO 13849-1

- SIL 2 according to IEC 61800-5-2

MOVIFIT safety options S11 and S12

| MOVIFIT® |

|

|

|---|---|---|

| Safety option | S11 | S12 |

| Specifically, these are | Safety-related electronics components with safe inputs and outputs | Parameterisable option cards with safe inputs and outputs |

| Schematic representation |

larger version – click here (JPG) |

larger version – click here (JPG) |

| Communication | PROFIsafe | PROFIsafe |

| Safety functions in accordance with EC 61800-5-2 |

|

|

| Safe inputs and outputs |

|

Two Variants: S12A

S12B

|

| Operation | Fieldbus to PROFIsafe | Fieldbus to PROFIsafe and independent operation |

Hygienic design

Satisfy the demanding hygiene requirements in the food and beverage industry as well as in the chemical and pharmaceutical industry with our HygienicPlus design. You can upgrade the design of the MOVIFIT® FC, already optimised for use in the field, and gain the ideal conditions for use in the wet area.

- Degree of protection IP69k in accordance with DIN 40050-9 (MOVIFIT® housing closed and all cable bushings sealed according to the relevant degree of protection)

- Easy-to-clean housing (self-draining design)

- Surface with anti-adhering properties

- High impact resistance of the surface against mechanical damage

- Compatibility with cleansing agents having the following properties:

- Resistance to temperature fluctuations

- Condensation

- Suction effect (pressure compensation)

Energy efficiency

Efficient control mode for IE2 to IE4 motors and energy-optimised brake control. Operate your plant efficiently with our MOVIFIT® FC application inverter. This can be graduated and scaled according to requirements of the end customer.

| Efficiency classes | IE1 Standard Efficiency |

IE2 High Efficiency |

IE3 Premium Efficiency |

IE4 Super Premium Efficiency |

|---|---|---|---|---|

| DR series Line Start Permanent Magnet (LSPM) motors | DRE 80MJ4 | DRP 90MJ4 | DRU 90LJ4 | |

| AC motors of the DR.. series | DRS 90M4 | DRE 90L4 | DRP 100M4 |

Areas of application

For flexible field-oriented drive solutions with MOVIFIT® FC the focus is on complex handling and simple lifting applications in the transport, logistics and automobile industry and in the food and beverage industry:

- Dynamic pallet conveyors

- Simple skid conveyor technology

- Simple and small lifting applications

- Rotary tables

- Corner transfer units

- Container and crate transport

- Baggage handling

- Accumulating conveyor

- Travel axes, switch control, marking out for electrified monorail systems